Hollywood Manufacturing, Inc. is a full service machine shop with manufacturing capabilities such as material cut off, hot forging, centerless grinding, CNC turning/milling, conventional turning/milling, drilling, broaching, thread rolling, part marking and etc. We work with a wide range of alloys that include Inco 718, A-286, H-11, 13-8 MO, MP-35, 17-4, 8740, 4340, 4140, Titanium and other alloys.

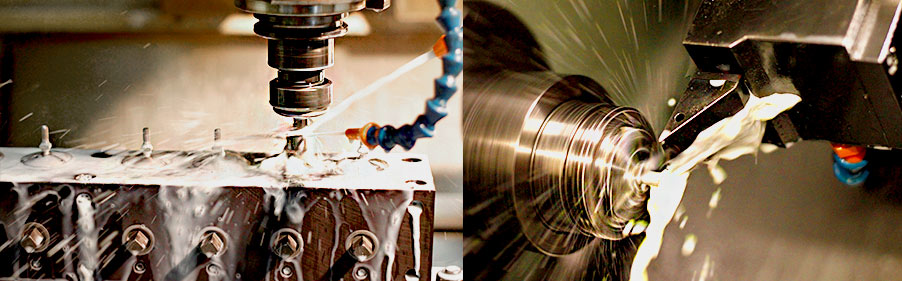

Our CNC department utilizes state of the art machinery to achieve the highest quality in manufacturing. We have the capability and the knowledge to assist you with your precision turning, as well as milling operations, such as dovetail cutting, slotting, broaching, contour forming and other precision, close tolerance operations.

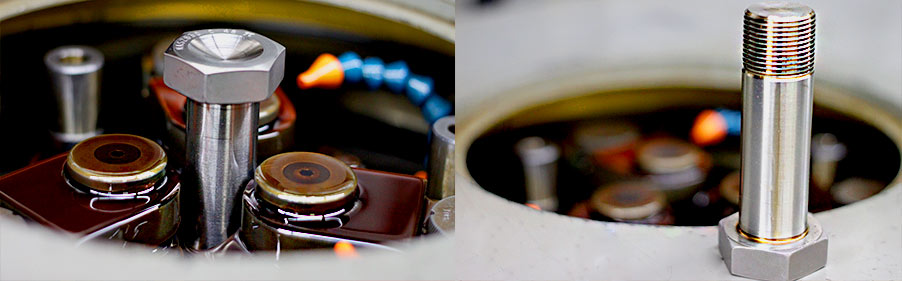

Our thread rolling department is equipped with flat-die thread rolling machines and three-die cylindrical thread rollers, and has cold rolling as well as hot rolling capabilities. We can roll thread sizes ranging from 6-32 to 1.250-12 on tough materials such as Inco 718, A-286, H-11 and Waspaloy.

Hollywood Manufacturing, Inc. started as a small service machine shop that specialized in grinding and thread rolling, therefore centerless grinding is one of Hollywood Manufacturing’s core niches. We have more than 40 years experience in centerless grinding and can assist you with your special grinding operations.

Whether it’s for a complete part or a specific operation, we invite you to submit your RFQs for your special inquiries. We are always committed to delivering high quality parts, quick on-time turnaround, and exceptional customer service.